During the factory tour at Mediaprint, which is Austria’s largest print media publisher, the WGA team in Vienna was invited to take a look behind the scenes at the Vienna-Inzersdorf printing centre, which produces the Kronen Zeitung, Kurier, Die Presse and Der Standard daily newspapers as well as other titles, using the offset printing process on up to eight printing presses at the same time. The tour started on the roof of the building, where we were able to marvel at the impressive system of solar panels (1350kW PEAK). The tour then took us to the office wing of the factory. The modernised offices were particularly impressive. These have been designed primarily as open-plan offices, but they also provide retreats for employees. The open-plan design and modern facilities create a pleasant working atmosphere and plenty of space for concentrated work or personal discussions. The offices were bright and friendly and the furniture, as well as the acoustic partitions, matched the colours of the respective departments.

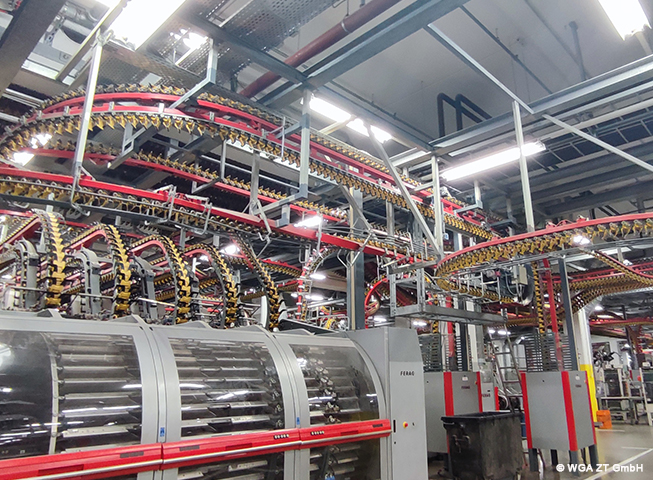

The tour then took us to the production facilities where around 2,000,000 newspapers are printed every day. Huge rolls (weighing 1 tonne or 20 km of paper per roll!) of newsprint in various sizes and qualities were stored in the paper roll warehouse. The quantity of paper rolls (capacity up to 2000 rolls) was impressive and illustrated the logistical challenge behind the production of daily newspapers. Every day, up to 300 rolls (10 lorry loads) are needed, which are transported from the unpacking stations to the printing towers by autonomous LGVs (Laser Guided Vehicles). At the same time, the printing inks are pumped from holding tanks (around 10 tonnes of ink per week) to the printing press using high-pressure pipes (120 bar). During offset printing, the printed image is first transferred from the aluminium printing plate to a rubber blanket and from there to the paper. Each of the three printing towers is eleven metres tall and the paper runs through the machine at speeds of up to 25 mph.

We visited various building services rooms while we were there, including those in the sprinkler distribution system for the paper store and the pressroom, the boiler room, the compressed air centre, the cooling towers and the ventilation systems for the printing halls. Most of the systems are redundant so as to prevent potential production downtimes. An additional argon extinguishing system for the six transformers (1250kVA each) ensures the safety of employees in the event of an emergency.

The tour of the Mediaprint factory was an extremely impressive experience overall. The combination of state-of-the-art technology and logistical challenges impressed every member of our team.